We’ve taken a great product and made it even better!

We’ve taken a great product and made it even better!

Adjustable Handles, also known as Clamp Levers, have been on the market for a long time. They are most commonly designed with a single handle extending from a hub with a tear-drop or ball style grip. Adjustable Handles are widely used as a ratchet style handle for clamping on machinery in a variety of industries including packaging, processing, printing, and machine tool.

This product has stood the test of time; however,

Morton Machine Works has received feedback from its customers pertaining to the design and durability of the handle. Depending on the application, customers have told us these handles sometimes break or “snap.” This can happen for several reasons, but we found the most common cause to be over torque or “impact” tightening.

To more adequately meet the needs of our customers,

Morton Machine Works set out to design a new Adjustable Handle that would not only provide a more comfortable grip, but also improve durability. We’ve developed the new line of

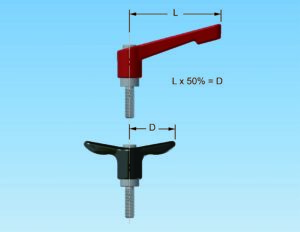

Adjustable T-Handles to compliment our existing Adjustable Handle product lines. By using the T-Handle design on adjustable handles, we’ve flattened the overall height of the product and reduced the radius, creating a smaller handle design that works better in confined spaces.

Morton has also improved durability in two ways. First, when you grip the

Adjustable T-Handle, you are applying torque on both sides of the hub rather than at one single point. This allows more uniform pressure on the handle. Second, the shorter handle radius reduces the risk of snapping the handle because you are applying the torque closer to the hub instead of at the end of a longer handle. More uniform clamping pressure applied closer to the hub, results in improved durability of the handle.

Why switch to the Adjustable T-Handle?

Simple answer:

It’s a more durable handle that is easier to grip. We’ve taken a great product and made it better!

We’ve taken a great product and made it even better!

Adjustable Handles, also known as Clamp Levers, have been on the market for a long time. They are most commonly designed with a single handle extending from a hub with a tear-drop or ball style grip. Adjustable Handles are widely used as a ratchet style handle for clamping on machinery in a variety of industries including packaging, processing, printing, and machine tool.

This product has stood the test of time; however, Morton Machine Works has received feedback from its customers pertaining to the design and durability of the handle. Depending on the application, customers have told us these handles sometimes break or “snap.” This can happen for several reasons, but we found the most common cause to be over torque or “impact” tightening.

To more adequately meet the needs of our customers, Morton Machine Works set out to design a new Adjustable Handle that would not only provide a more comfortable grip, but also improve durability. We’ve developed the new line of Adjustable T-Handles to compliment our existing Adjustable Handle product lines. By using the T-Handle design on adjustable handles, we’ve flattened the overall height of the product and reduced the radius, creating a smaller handle design that works better in confined spaces.

Morton has also improved durability in two ways. First, when you grip the Adjustable T-Handle, you are applying torque on both sides of the hub rather than at one single point. This allows more uniform pressure on the handle. Second, the shorter handle radius reduces the risk of snapping the handle because you are applying the torque closer to the hub instead of at the end of a longer handle. More uniform clamping pressure applied closer to the hub, results in improved durability of the handle.

Why switch to the Adjustable T-Handle?

Simple answer: It’s a more durable handle that is easier to grip. We’ve taken a great product and made it better!

We’ve taken a great product and made it even better!

Adjustable Handles, also known as Clamp Levers, have been on the market for a long time. They are most commonly designed with a single handle extending from a hub with a tear-drop or ball style grip. Adjustable Handles are widely used as a ratchet style handle for clamping on machinery in a variety of industries including packaging, processing, printing, and machine tool.

This product has stood the test of time; however, Morton Machine Works has received feedback from its customers pertaining to the design and durability of the handle. Depending on the application, customers have told us these handles sometimes break or “snap.” This can happen for several reasons, but we found the most common cause to be over torque or “impact” tightening.

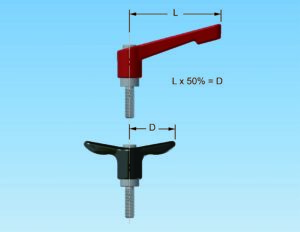

To more adequately meet the needs of our customers, Morton Machine Works set out to design a new Adjustable Handle that would not only provide a more comfortable grip, but also improve durability. We’ve developed the new line of Adjustable T-Handles to compliment our existing Adjustable Handle product lines. By using the T-Handle design on adjustable handles, we’ve flattened the overall height of the product and reduced the radius, creating a smaller handle design that works better in confined spaces.

Morton has also improved durability in two ways. First, when you grip the Adjustable T-Handle, you are applying torque on both sides of the hub rather than at one single point. This allows more uniform pressure on the handle. Second, the shorter handle radius reduces the risk of snapping the handle because you are applying the torque closer to the hub instead of at the end of a longer handle. More uniform clamping pressure applied closer to the hub, results in improved durability of the handle.

Why switch to the Adjustable T-Handle?

Simple answer: It’s a more durable handle that is easier to grip. We’ve taken a great product and made it better!