Morton Machine Works manufactures one of the industry’s largest selections of industrial thumb screws. These thumb screws are used in a variety of applications on equipment used in Metalworking, Aerospace, Automotive, and Medical Industries. They are manufactured from a variety of materials including carbon steel (C1215), stainless steel (303), brass (360), and Nylatron GS. Morton Machine Works offers most of its thumb screw products in both Inch and Metric sizes available from stock for same day shipping. If you have a special application that requires a “made to print” special, Morton Machine Works can manufacture a quality part made thumb screw in just a few weeks.

Call today for all your Tooling Component requirements!

Morton Machine Works manufactures one of the industry’s largest selections of industrial thumb screws. These thumb screws are used in a variety of applications on equipment used in Metalworking, Aerospace, Automotive, and Medical Industries. They are manufactured from a variety of materials including carbon steel (C1215), stainless steel (303), brass (360), and Nylatron GS. Morton Machine Works offers most of its thumb screw products in both Inch and Metric sizes available from stock for same day shipping. If you have a special application that requires a “made to print” special, Morton Machine Works can manufacture a quality part made thumb screw in just a few weeks.

Call today for all your Tooling Component requirements!

Morton Machine Works is a leading supplier of Spherical Washer Sets for industrial applications throughout the United States. Spherical Washer Sets, also commonly known as Equalizing Washers, are used in clamping applications to compensate for slight misalignment between threads and the workpiece. The top washer half has a convex surface that has a smaller hole ID than the bottom half concave surface. The full floating action of the two washers allow angle correction of up to 3 degrees when clamping. Spherical Washer Sets are commonly used for jig and fixture clamping as well as in applications for the Construction, Gas & Oil, and Metalworking Industries. Morton stocks a full line of spherical washer sets in Bolt Sizes from 3/32” through 3” including metric sizes from M6 ID through M30. Standard materials include case hardened carbon steel with a black oxide finish and 303 stainless steel. Many sizes are available from stock in 316 stainless steel, 304 stainless steel, 4140 through hardened steel, and galvanized finishes. Follow the link below to see the full representation of materials, sizes, and CAD available.

https://workholdingcomponents.mortonmachine.com/viewitems/workholding-components-washers/spherical-washers-self-aligning-washers

Morton Machine Works is a leading supplier of Spherical Washer Sets for industrial applications throughout the United States. Spherical Washer Sets, also commonly known as Equalizing Washers, are used in clamping applications to compensate for slight misalignment between threads and the workpiece. The top washer half has a convex surface that has a smaller hole ID than the bottom half concave surface. The full floating action of the two washers allow angle correction of up to 3 degrees when clamping. Spherical Washer Sets are commonly used for jig and fixture clamping as well as in applications for the Construction, Gas & Oil, and Metalworking Industries. Morton stocks a full line of spherical washer sets in Bolt Sizes from 3/32” through 3” including metric sizes from M6 ID through M30. Standard materials include case hardened carbon steel with a black oxide finish and 303 stainless steel. Many sizes are available from stock in 316 stainless steel, 304 stainless steel, 4140 through hardened steel, and galvanized finishes. Follow the link below to see the full representation of materials, sizes, and CAD available.

https://workholdingcomponents.mortonmachine.com/viewitems/workholding-components-washers/spherical-washers-self-aligning-washers

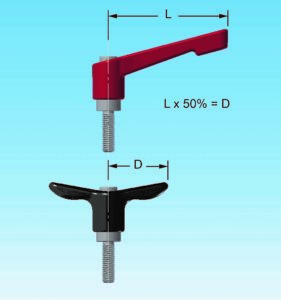

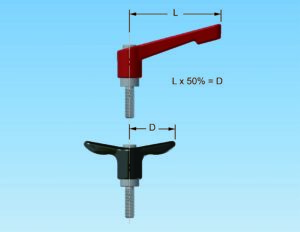

Adjustable Handles, also known as Clamp Levers, have been on the market for a long time. They are most commonly designed with a single handle extending from a hub with a tear-drop or ball style grip. Adjustable Handles are widely used as a ratchet style handle for clamping on machinery in a variety of industries including packaging, processing, printing, and machine tools.

This product has stood the test of time; however, over the years Morton Machine Works has received feedback from its customers pertaining to the design and durability of the handle. Depending on the application, customers have told us these handles sometimes break or “snap.” This can happen for several reasons, but we found the most common cause is “over torque” or “impact” tightening. To more adequately meet the needs of our customers, Morton Machine Works set out to design a new Adjustable Handle that would not only provide a more comfortable grip, but also improve durability. We’ve developed the new line of Adjustable T-Handles to complement our existing Adjustable Handle product lines. By using the T-Handle design on adjustable handles, we’ve flattened the overall height of the product and reduced the radius, creating a smaller handle design that works better in confined spaces. Morton has also improved durability in two ways. First, when you grip the Adjustable T-Handle, you are applying torque on both sides of the hub rather than at one single point. This allows more uniform pressure on the handle. Second, the shorter handle radius reduces the risk of snapping the handle because you are applying the torque closer to the hub instead of at the end of a longer handle. More uniform clamping pressure applied closer to the hub, results in improved durability of the handle. Why switch to the Adjustable T-Handle ? It’s a more durable handle that is easier to grip !

We’ve taken a great product and made it better

Adjustable Handles, also known as Clamp Levers, have been on the market for a long time. They are most commonly designed with a single handle extending from a hub with a tear-drop or ball style grip. Adjustable Handles are widely used as a ratchet style handle for clamping on machinery in a variety of industries including packaging, processing, printing, and machine tools.

This product has stood the test of time; however, over the years Morton Machine Works has received feedback from its customers pertaining to the design and durability of the handle. Depending on the application, customers have told us these handles sometimes break or “snap.” This can happen for several reasons, but we found the most common cause is “over torque” or “impact” tightening. To more adequately meet the needs of our customers, Morton Machine Works set out to design a new Adjustable Handle that would not only provide a more comfortable grip, but also improve durability. We’ve developed the new line of Adjustable T-Handles to complement our existing Adjustable Handle product lines. By using the T-Handle design on adjustable handles, we’ve flattened the overall height of the product and reduced the radius, creating a smaller handle design that works better in confined spaces. Morton has also improved durability in two ways. First, when you grip the Adjustable T-Handle, you are applying torque on both sides of the hub rather than at one single point. This allows more uniform pressure on the handle. Second, the shorter handle radius reduces the risk of snapping the handle because you are applying the torque closer to the hub instead of at the end of a longer handle. More uniform clamping pressure applied closer to the hub, results in improved durability of the handle. Why switch to the Adjustable T-Handle ? It’s a more durable handle that is easier to grip !

We’ve taken a great product and made it better

Morton Machine Works offers a wide variety of handles and knobs made from plastic, steel, stainless steel, cast iron, and aluminum. Whether you need a couple replacement handles for that project in your garage, or if your looking for 5000 pieces to be used on your production machinery… Morton can help. Morton works with many well known OEM’s to supply their tooling component needs from concept prints all the way to final assembly. The hand knobs and handles are available in all common Inch and Metric sizes on the shelf ready to ship same day. Morton Machine Works also does “made to print” specials… if you don’t see exactly what you need on the website, email us at sales@mortonmachine.com and we can work with you on a solution that best fits your handle applications.

Morton Machine Works offers a wide variety of handles and knobs made from plastic, steel, stainless steel, cast iron, and aluminum. Whether you need a couple replacement handles for that project in your garage, or if your looking for 5000 pieces to be used on your production machinery… Morton can help. Morton works with many well known OEM’s to supply their tooling component needs from concept prints all the way to final assembly. The hand knobs and handles are available in all common Inch and Metric sizes on the shelf ready to ship same day. Morton Machine Works also does “made to print” specials… if you don’t see exactly what you need on the website, email us at sales@mortonmachine.com and we can work with you on a solution that best fits your handle applications.

Morton Machine Works manufactures one of the industry’s largest selections of industrial thumb screws. These thumb screws are used in a variety of applications on equipment used in Metalworking, Aerospace, Automotive, and Medical Industries. They are manufactured from a variety of materials including carbon steel, stainless steel, brass, and nylatron. Morton offers most thumb screw products in both Inch and Metric sizes available from stock for same day shipping. If you have a special application that requires a “made to print” special, Morton Machine Works can work with you to produce a quality part made to your specifications usually within a few weeks.

Morton Machine Works manufactures one of the industry’s largest selections of industrial thumb screws. These thumb screws are used in a variety of applications on equipment used in Metalworking, Aerospace, Automotive, and Medical Industries. They are manufactured from a variety of materials including carbon steel, stainless steel, brass, and nylatron. Morton offers most thumb screw products in both Inch and Metric sizes available from stock for same day shipping. If you have a special application that requires a “made to print” special, Morton Machine Works can work with you to produce a quality part made to your specifications usually within a few weeks.

We’ve taken a great product and made it even better!

Adjustable Handles, also known as Clamp Levers, have been on the market for a long time. They are most commonly designed with a single handle extending from a hub with a tear-drop or ball style grip. Adjustable Handles are widely used as a ratchet style handle for clamping on machinery in a variety of industries including packaging, processing, printing, and machine tool.

This product has stood the test of time; however, Morton Machine Works has received feedback from its customers pertaining to the design and durability of the handle. Depending on the application, customers have told us these handles sometimes break or “snap.” This can happen for several reasons, but we found the most common cause to be over torque or “impact” tightening.

To more adequately meet the needs of our customers, Morton Machine Works set out to design a new Adjustable Handle that would not only provide a more comfortable grip, but also improve durability. We’ve developed the new line of Adjustable T-Handles to compliment our existing Adjustable Handle product lines. By using the T-Handle design on adjustable handles, we’ve flattened the overall height of the product and reduced the radius, creating a smaller handle design that works better in confined spaces.

Morton has also improved durability in two ways. First, when you grip the Adjustable T-Handle, you are applying torque on both sides of the hub rather than at one single point. This allows more uniform pressure on the handle. Second, the shorter handle radius reduces the risk of snapping the handle because you are applying the torque closer to the hub instead of at the end of a longer handle. More uniform clamping pressure applied closer to the hub, results in improved durability of the handle.

Why switch to the Adjustable T-Handle?

Simple answer: It’s a more durable handle that is easier to grip. We’ve taken a great product and made it better!

We’ve taken a great product and made it even better!

Adjustable Handles, also known as Clamp Levers, have been on the market for a long time. They are most commonly designed with a single handle extending from a hub with a tear-drop or ball style grip. Adjustable Handles are widely used as a ratchet style handle for clamping on machinery in a variety of industries including packaging, processing, printing, and machine tool.

This product has stood the test of time; however, Morton Machine Works has received feedback from its customers pertaining to the design and durability of the handle. Depending on the application, customers have told us these handles sometimes break or “snap.” This can happen for several reasons, but we found the most common cause to be over torque or “impact” tightening.

To more adequately meet the needs of our customers, Morton Machine Works set out to design a new Adjustable Handle that would not only provide a more comfortable grip, but also improve durability. We’ve developed the new line of Adjustable T-Handles to compliment our existing Adjustable Handle product lines. By using the T-Handle design on adjustable handles, we’ve flattened the overall height of the product and reduced the radius, creating a smaller handle design that works better in confined spaces.

Morton has also improved durability in two ways. First, when you grip the Adjustable T-Handle, you are applying torque on both sides of the hub rather than at one single point. This allows more uniform pressure on the handle. Second, the shorter handle radius reduces the risk of snapping the handle because you are applying the torque closer to the hub instead of at the end of a longer handle. More uniform clamping pressure applied closer to the hub, results in improved durability of the handle.

Why switch to the Adjustable T-Handle?

Simple answer: It’s a more durable handle that is easier to grip. We’ve taken a great product and made it better!

Morton Machine Works is a manufacturer of quality tooling components supplying to industrial distributors, catalog houses, and OEM's throughout the world. In addition to offering a full line of standard components, Morton has the engineering experience and capabilities to produce custom parts to your specifications.